How to Bore Out an Engine

Ifyou see scratches in the bore it needsto be bored. Ifyou see scratches on you crank journals you crank needsto be turned.

Installing Cylinder Sleeves Knowyourparts

Ifyou see scratches in the bore it needsto be bored.

. In this video we bore small engine cylinders. Makes small engine cylinders and parts. A boring bar is a specialized piece of machinery that is made for the cylinder boring process.

Kohler K Series Engines Briggs and Stratton Engines Tecumseh Much More. From a performance standpoint boring an engine could give you more horsepower and torque as it will change the engines displacement. How to Bore Out an Engine Cylinder Step 1.

How do you know if your engine needs boring. During a boring job your engine might receive horsepower and torque depending on its displacement. Table of contents Does Boring Out An Engine Increase Horsepower.

An engine can be boosted in displacement by having the piston travel farther in the cylinder. Boring an engine involves using machines to widen and taper the cylinders. Feb 21 2013.

Browse Quality Aftermarket Reproduction Parts. Attach the proper-size honing tool for your cylinder to a power drill or similar tool that will. Position the cylinder part in a holder so that it remains locked still when working on it with a boring cutter.

How do you bore out an engine. There are different types of engines so engines can have different displacement rates. Put the ring in the bore and square it up the old piston works well.

Dismantle the cylinder and remove it from the engine. When an engine is being bore the cylinders must be enlarged and tapered using rollers. Bored Over Engine is a Common Mean name for a computer program.

What Happens When You Bore Out An Engine. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Measure the gap in the ring with a feeler gauge at the top of the bore and a couple times as you go down the bore to the very bottom.

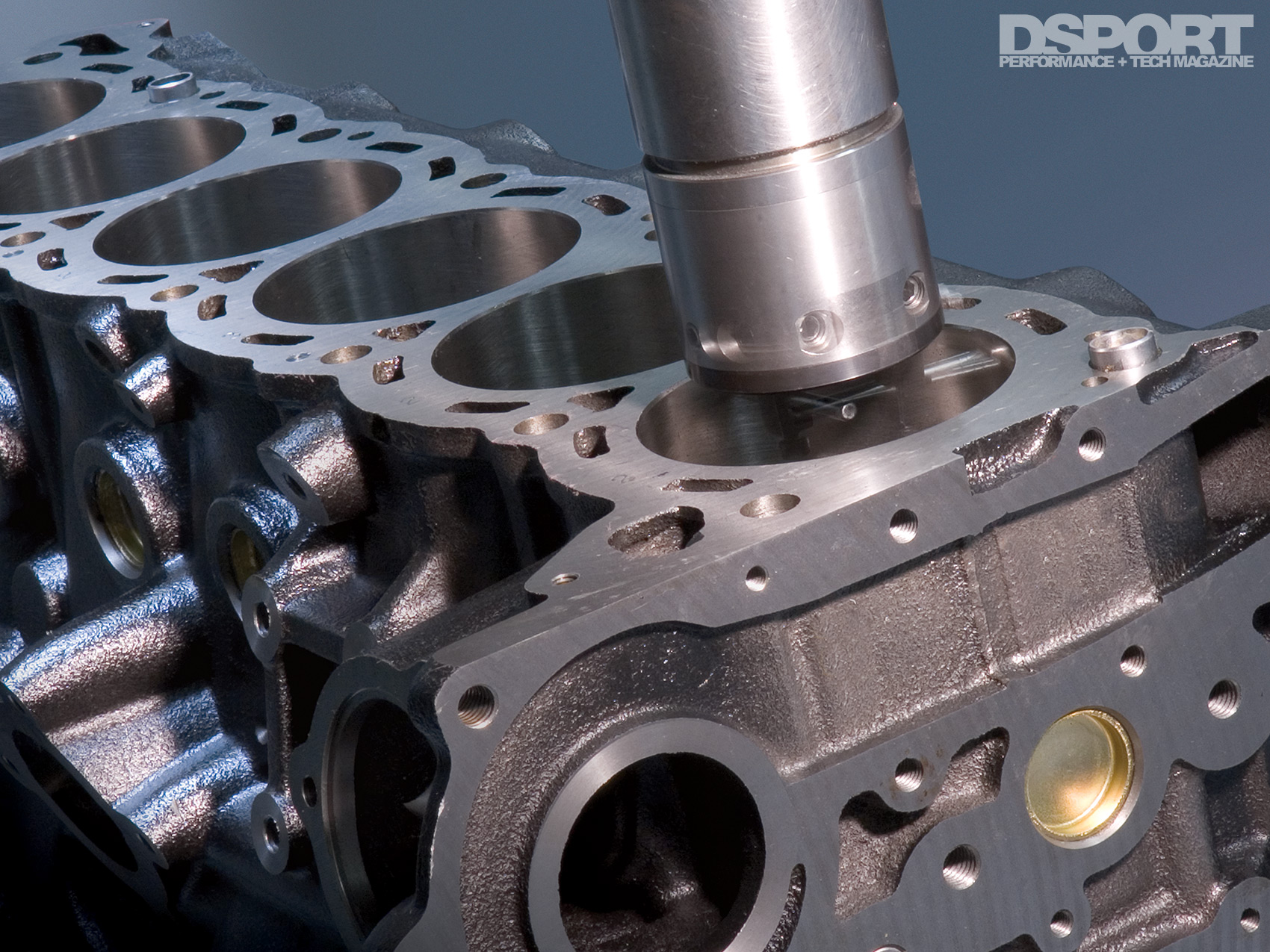

In general the greater your engines displacement the more power it can create. How much does it cost to bore out an engine. The first step in the cylinder boring process is mounting the block in the boring bar.

I charge 68 a hole but that also includes. I have received a lot of request showing how I bore these cases out. If you have any questions and are in the Grand Rapids Michigan area call 616-430-3.

Pistones which are internal swept volumes make. Position the cylinder part in a holder so that it remains locked still when working on it with a boring cutter tool. Ad We Dont Just Sell Parts.

Mounting the cylinder on a milling machine or lathe makes it difficult to ensure the. Reboring an engine will be commonly done when the piston piston rings and the cylinder becomes damaged either due to wear and tear or excessive usage. How To Bore Out An Engine Cylinder.

What Does Boring Out An Engine Do. When the cylinders wall becomes damaged it can be rebored to a larger size and larger pistons will be used in its place and after the reboring is done the next step will be a process known as sleeving which. Use a socket wrench and sockets and various crescent.

Engines are cleared of debris with the help of boring their cylinders out. Furthermore by rocking the engine the crankshaft arm or lever of the engine is pushed slightly harder. Dismantle the cylinder and remove it from the engine.

Measure the crank with a mic and measure the bore for out of round and taper with a bore gage. Locate the boring cutter parallel to the cylinder so that it is centered. There is no need to replace the main bearing cap bolts with.

When stripping down an engine always replace the cylinder head bolts and rod bolts. Mounting the engine block. If you have an engine apart a quick check is to use an old ring.

Make sure the boring cutter is parallel to the cylinder and that its position is determined by the cylinder. Port chamfering honing to finished size chamfering top of cyl and stamping cyl size on blockrestrictor modification and for a additional 85 you can get it hot tankedchemical washed and oiled ready to assemble. Posted by McNally Published April 6 20221106 pm Make sure that the cylinder is turned upward and straight.

What does it cost to bore out an engine. If your engine suffers from a scored cylinder and is suffering from low compression you may look at reboring the engine and while you are at it you may just as well bore it out to a greater capacity and fit new pistons to match the larger bore. A flush mount is necessary in order to attain a perpendicular bore.

This is a video demonstrating how to bore out a GY6 150cc 157QMJ engine. For cylinders based on milling machines round cylinders are turned to bore and increase displacement since the engine is driven by these cylinders. For cylinder borings you should allow the boring tool to lower into the cylinder and engage the bore and round the hole at the same time.

How To Hone Engine Cylinders The Right Way Youtube

Engine Block Tech 101 Go Bigger Or Go Stronger The Right Way

Engine Will Boring A Cylinder Affect Its Longevity Thereafter Motor Vehicle Maintenance Repair Stack Exchange

No comments for "How to Bore Out an Engine"

Post a Comment